Crawler wire saw machine automatic cutting wireless remote control

DH12S-2R-LD-485 crawler rope saw cutting remote control

Description

Crawler wire saw automatic cutting remote control is suitable for crawler wire saw cutting machines,Use 485Modbus RTU protocol to control the left and right crawler inverters,As well as large motor frequency conversion speed regulation start and front, rear, left and right direction controllers。And the working current of the large motor inverter can be read through the 485-Modbus RTU protocol,Analysis and comparison of large motor current at startup,Automatically adjust left and right track speeds in real time,Realize automatic cutting function。

1.Using 433MHZ wireless communication technology,Wireless operating distance 100 meters。

2.Adopt automatic frequency hopping function,Use 32 sets of wireless remote controls at the same time,No effect on each other。

3.Supports all frequency converters with 485-Modbus RTU protocol,The currently adapted inverter brands include: Shanghai Xielin、Fuji、Huichuan、Zhongchen、INVT、Yasukawa Tatsu。If the brand is not adapted, please contact us for customization.。

4.Support large motor inverter startup、speed regulation、Current reading。

5.Support left and right crawler inverter speed adjustment、start up、Front and rear left and right controls。

6.Support left and right crawler inverter linear correction,Keep the machine moving in a straight line。

7.Support wire saw automatic cutting function,According to the large motor current information,Automatically adjust left and right track speeds in real time。

8.It is also compatible with direct IO output to control motor start and stop.,Analog voltage output controls motor speed。

②Mode switch:

Adopt 2-speed switch,Can switch between automatic and manual modes,There will be corresponding mode display switching on the display screen.。

③ Enable:

Combination button,Some operations require pressing and holding the enable button to operate,See the description of each switch for details.。

④Large motor switch:

Adopt 3-speed reset switch,flip this switch,Can control forward and reverse rotation of large motors,The status will remain after letting go,There will be a corresponding display on the display,↑Arrow indicates forward rotation,↓Arrow indicates reversal。

⑤Small motor forward/reverse switch:

Adopt 3-speed self-locking switch,flip this switch,Can control the small motor to move forward and backward,There will be a corresponding display on the display,↑Arrow means moving forward,↓The arrow indicates going back。

⑥ Remote control power switch:

The large motor speed value changes by approximately 0.2 units, Using multi-turn encoder knob,Turn the knob,Adjust the large motor speed S1。1 frame per turn, Rapid rotation can quickly modify the large motor speed value。

⑦Small motor turning switch:

Adopt 3-speed reset switch,Turn this switch in manual mode,Can control small motor to turn left and right,The remote control will automatically stop this action after letting go.。 In forward state,flip this switch,There will be a corresponding display on the display,←Arrow indicates left turn,→The arrow indicates turning right。 In retreat state,flip this switch,There will be a corresponding display on the display,←Arrow indicates left turn,→The arrow indicates turning right。 Press and hold to enable,Then flip this switch,Can perform in-situ turning function,Turn faster。

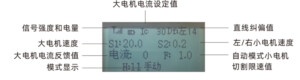

⑧Speed regulation of large motor :

The large motor speed value changes by approximately 0.2 units, Using multi-turn encoder knob,Turn the knob,Adjust the large motor speed S1。1 frame per turn, Rapid rotation can quickly modify the large motor speed value。

⑨Small motor speed regulation:

(Linear deviation correction) adopts multi-turn encoder knob,In manual mode,Each time the knob is turned 1 step,The speed value of the small motor changes by about 0.1 unit,Quick rotation can quickly modify the speed value of the small motor。In automatic mode,Press enable button,Then rotate 1 frame each time,The small motor speed limit value F changes by about 0.1 unit,Quick rotation can quickly modify the speed limit value of small motors。Press enable button,Turn knob right,Straight line correction display:Df:left,Each turn of the knob increases by 1 unit.;Turn knob left,Straight line correction display:Df:right,Each turn of the knob increases by 1 unit.;Each correction unit corresponds to the motor speed regulation AVI voltage of about 0.02V.。

Product installation steps

1.Install the receiver into the electrical cabinet through the buckle on the back,Or install it in the electrical cabinet through the screw holes at the four corners of the receiver。

2.Refer to our receiver wiring diagram,Check against your field equipment,Connect the device to the receiver via wires。

3.After the receiver is fixed,The antenna equipped with the receiver must be connected,And install or place the outer end of the antenna outside the electrical cabinet,It is recommended to place it on the top of the electrical cabinet for the best signal effect.,It is prohibited to leave the antenna unconnected,Or place the antenna inside the electrical cabinet,This may result in poor signal and unusable。

4.Finally, install the batteries in the remote control,Tighten the battery cover,Then turn on the remote control power switch,The remote control display will show the normal working interface.,You can perform remote control operation。

Receiver installation dimensions

Receiver wiring reference diagram

Remote control parameter settings

Enter the remote control background parameter method:Move the mode switch to manual mode,Adjust the small motor speed to 25, or 0、10、20、40、50,Pull the forward rotation switch of the large motor upward 3 times in a row,Pull down 3 times in succession;

Use the "Small Motor Speed Adjustment" knob to turn pages,After pressing enable, turn the small motor speed control knob to modify the parameters.; After modification,Turn the page to the end,Select Save and Exit,Press the enable button to exit the menu;

The parameters are as follows: Maximum current:Large motor current feedback value range,Setting range 15-200A,Default 60;

Speed control parameters:Automatic mode small motor automatically accelerates speed,The smaller, the faster,Setting range 200-1500, Default 1000;

Deceleration parameters:Set the upper limit for allowed motor speed changes,When the current change exceeds this value,will slow down。 The smaller,The left and right motors decelerate faster,Range 05-12,Default 06;

Start self-locking: Acceleration a1:The larger the motor, the faster the speed increases.,Range 00-06,Default 01;

Deceleration a2:The larger the motor speed is, the faster it will decrease.,Range 00-06,Default 02;

Enable speed adjustment:Is it necessary to press Enable to adjust the speed of small motors?,00Disable,01enable,Default 01;

Will the large motor automatically maintain self-locking after the forward and reverse switch is released?,00do not maintain,01Keep,Default 01;

maximum walking:Maximum speed of left and right motors,Range 10-100,Default 50;

Cutting current:Maximum cutting current,The screen displays the IC value,Range 15-160,Default 30,Screen corresponding display IC:30。The upper limit of this parameter = maximum current x80%;

Default speed limit:The default small motor automatic cutting speed at startup,Range 00-100,Default 10,The screen should display F1.0,This parameter is only accurate when the maximum walk is set to 50。

wireless channel:Default 10,When the remote control signal is unstable,Or when there is signal interference on site,This parameter can be modified,switch channel,avoid distractions;

speed limit offset:Small motor automatic cutting speed upper limit,Range 00-200,Default 60,The screen corresponds to display 6.0;Display value upper limit = speed limit offset × 0.1;

largest host:Maximum speed of large motor,Range 10-100,Default 50;

mbus device (required):Large motor inverter model selection,Range 00-03,Default 03;

00-Shanghai Xielin 01-Fuji

02-INVT 03-Huichuan (Zhongchen、Robin Kang)

sbus device (required):Small motor inverter model selection,Range 00-05,Default 03;

00-Shanghai Xielin 01-Fuji

02-INVT 03-Huichuan (Zhongchen、Robin Kang)

04-Yasukawa Tatsu 05-None

Frequency converter parameter setting

1.Command source selection:Communication command channel

2.Main frequency source selection:communication given

3.baud rate:19200

4.Data format:No checksum,Data format<8-N-1>

5.Local address:Left frequency converter is set to 1,The right frequency converter is set to 2,Large motor inverter is set to 3

Remote control operating instructions

1.Machine powered on,Remote control power on,Enter the remote control background,Set the background parameters of the remote control,The main thing is to set the inverter models of small motors and large motors (skip this step if the machine manufacturer has set it);

2.Set the inverter parameters (skip this step if the machine manufacturer has set them);

3.Switch the remote control to manual mode,Then use the remote control to move the machine to the working position;

4.In manual mode,Set the large motor cutting current setting value IC,Set the maximum motor speed;

5.Switch to automatic mode,Set the small motor cutting speed limit F value;

6.In automatic mode,Turn the big motor switch to forward to start the big motor,Then turn the small motor switch to forward or reverse gear,The remote control enters automatic cutting mode,Start cutting。

1.Please keep it at normal temperature and pressure,Use in dry environment,Extend service life。

2.Please avoid getting exposed to rain、Use in abnormal environments such as blisters,Extend service life。

3.Please keep the battery compartment and metal shrapnel area clean。

4.Please avoid squeezing and dropping the remote control, which may cause damage.。

5.Not used for a long time,Please remove the battery,And store the remote control and batteries in a clean and safe place。

6.Pay attention to moisture-proof and shock-proof when storing and transporting。

1.Please read the instructions carefully before use,Operation by non-professionals is prohibited。

2.Please replace the battery in time when the battery is too low,Avoid errors caused by insufficient battery power causing the remote control to be inoperable.。

3.Need repair,Please contact the manufacturer,If the damage is caused by self-repair,The manufacturer will not provide warranty。

(Remark:Product upgrade or upgrade situation,When purchasing products, please contact the sales staff for the latest product status)